For ordinary consumers, the Christmas season of 2019 may be a great opportunity to reward themselves after a year's hard work, but for manufacturers and media in the field of consumer electronics, things are far from easy. Because just a few days later, the CES consumer electronics show in 2020 will be held, followed by the MWC world mobile conference in February. In other words, although it is in the "double day" holiday period, the pace of new products can never stop.

This week, for example, MICROSTAR, a leading PC maker, unveiled its latest notebook creator 17. As a product of professional design, creator 17 is destined to be out of contact with mass consumers, so why do we mention it? Because the biggest feature of this notebook is that it uses the world's first notebook screen panel based on miniled technology. This not only means that it may become one of the best display notebook products in 2020, but more importantly, it may be the cheapest miniled related products ever. Because of this, we think it's time to tell you some of the "truth" about miniled and the relationship between it and another name, which is very confusing.

First of all, you need to know a basic chemical knowledge about LED screen. I believe that the first thing you think about is the current AMOLED panel technology mixed in the mobile phone. But the problem is that if you connect "miniled", "microled" and AMOLED, you just make a big mistake. Why? Because the full name of AMOLED is active matrix organic light emitting diode. Please pay attention to the word "organic", which means that in AMOLED, or all OLED screens, the luminescence depends on the organic compound coating between the positive and negative electrodes - when the electrons pass through the organic matter, it will produce a mechanism called excitation action on the organic matter, and then make the organic matter emit color light.

However, for both minileds and microleds, their internal light-emitting depends not on organic coating, but on inorganic metal semiconductors, such as gallium phosphide, gallium nitride, zinc selenide, aluminum carbonitride, etc., which are more "ancient" in nature and simpler in principle. Is it a little dizzy? It doesn't matter. We can see the difference between organic LED and inorganic led by putting two pictures. In short, OLED is the organic thin film in the electrode interlayer, so OLED must be a thin "layer" in appearance and shape. Even if the OLED with only one pixel in the figure below is just like paper in appearance.

In contrast, the inorganic LED technology that miniled and microled are based on is much earlier than that of organic LED. As early as 1961, Texas Instruments Company discovered the principle of metal semiconductor stimulated light-emitting. Then in 1962, General Electric developed the world's first practical inorganic light-emitting diode. It is this finished product that determines the appearance of most of the future inorganic light-emitting diodes:

Well, you are right. This is the most typical inorganic led. If the organic LED is a composite film, then the inorganic LED is a small light bulb. This is not only due to their different circuit structures, but also determines their differences in product form and even use mode. The differences between miniled and microled, backlight and screen clarify the essence of inorganic light-emitting diodes, or "light bulbs" of miniled and microled. Then we can finally understand the crucial differences in technology, form and use.

Apple's Pro display XDR is one of the cheapest Mini LED backlighting displays at present. You can see that it's cheap. To put it simply, mini LED is a "small LED lamp bead" - this small one is smaller than ordinary LED bulbs. But please note that each of its light emitting units (or each "bulb") is not small enough to be used as a screen pixel. Therefore, when we say "miniLED screen", this is actually a wrong statement, because miniLED itself cannot be used as a screen panel, and its real purpose is actually the backlight module for LCD screen.

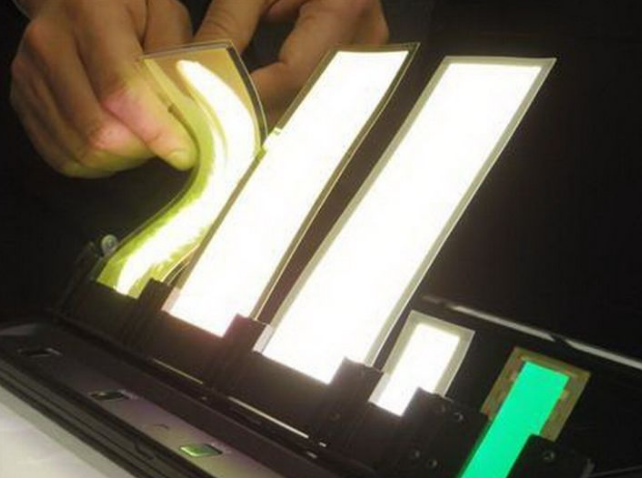

Compared with the traditional side backlight or the old straight down backlight, the advantages and disadvantages of miniled are very simple and rough. The first advantage is that each backlight "bulb" is smaller, so it can achieve a more precise dynamic backlight effect. While effectively improving the brightness and contrast of the screen, it can also suppress the glare caused by the traditional large bulb dynamic backlight between the bright and dark areas of the screen. The disadvantages are high energy consumption, high heating and high cost caused by high-density LED backlight module, and the problem of heavy screen caused by LCD in essence. We need to know that the existing miniled display in the industry basically has no less than 20000 pieces of products. Because of the small screen size, the mini LED module scale of Creator 17 of MICROSTAR is correspondingly "shrunk", so it is expected to become the cheapest miniled backlight screen device ever, that's all. But when it comes to high cost, minileds are not enough to see in front of microleds. Because the essence of microled is to make the "lamp beads" on miniled smaller and more dense, and then use the whole "led lamp panel" as a self luminous display panel. In a sense, the essence of microled is exactly the same as the LED billboard on the street, except that the density of the light beads on it is millions to tens of millions of times higher.

Sony Crystal LED system, the only micro LED screen on sale at present, is equipped with $5.8 million at the top. Compared with organic light-emitting diode (OLED), micro LED based on the principle of inorganic light-emitting diode belongs to self light-emitting screen panel as well as a series of advantages, such as high brightness, ultra-low delay, and large viewing angle. Moreover, because inorganic light-emitting diodes are based on metal semiconductors (rather than organic substances) with more stable properties and lower resistance, they have the advantages of lower power consumption, higher temperature and low temperature resistance and longer service life compared with OLEDs. In this case, the cost is so high that almost no one can afford it. Maybe it's just the only disadvantage of microled.

|

What are the differences, advantages and disadvantages of OLED, Mini LED and Micro LED?  Previous News: [more..] Month News archive All News List |